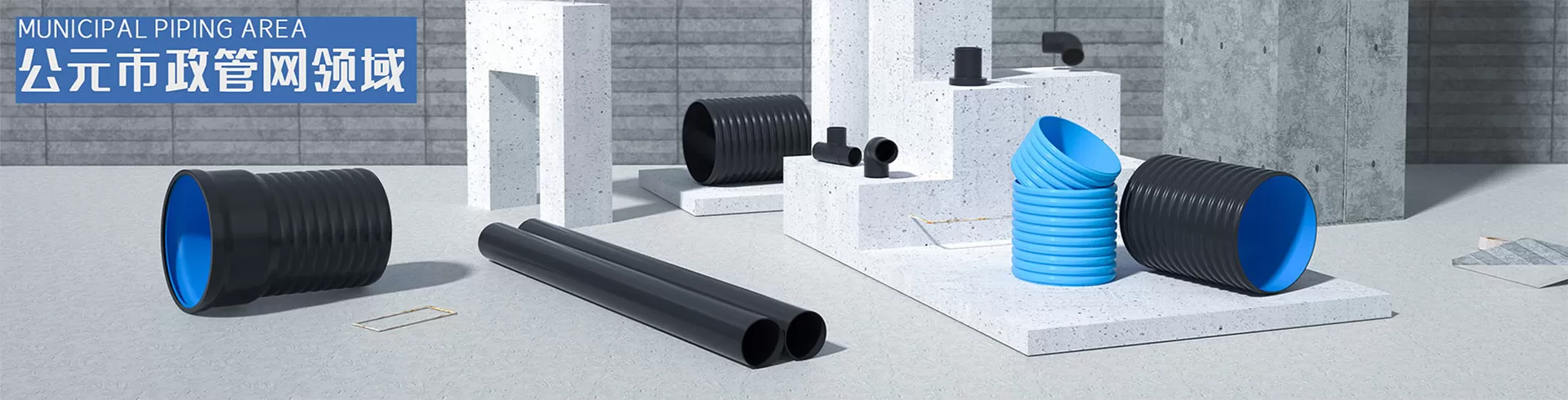

In recent years, with the rapid advancement of infrastructure building, the performance and quality of pipeline materials have become the focus of the industry. As a representative of new types of pipes, HDPE-M double-wall corrugated pipes are gradually reshaping the pipeline industry pattern with their excellent high-ring stiffness characteristics.

HDPE-M double-wall corrugated pipes are made of high-density polyethylene modified materials, and through the unique double-wall corrugated structure design, the ring stiffness of pipes is significantly improved. According to industry standards, its ring stiffness grade can reach SN16 or even higher, which is several times higher than that of traditional pipes. This high ring stiffness characteristic enables pipelines to withstand greater external pressure, especially in municipal drainage, underground pipe network laying and other scenarios, effectively reducing the risk of pipeline deformation and extending the service life to more than 50 years.

technological innovation is the core driving force for the high ring stiffness of HDPE-M double-wall corrugated pipes. Taking Hubei AD Building Materials Co., Ltd. as an example, the modified high-density polyethylene double-wall corrugated pipes developed by it have reached three times the national standard through material optimization and structural innovation, and the ring stiffness has been significantly enhanced. The advantages of

high ring stiffness have been fully verified in practical applications. The product performs well in municipal drainage, farmland irrigation and other fields, effectively solving the problems of easy damage and high maintenance cost of traditional pipes.

With the growth of market demand for high-quality pipes, the application scenarios of HDPE-M double-wall corrugated pipes continue to expand. From urban drainage system to industrial wastewater transportation, from underground pipe network construction to farmland water conservancy projects, high-ring stiffness pipes are gradually replacing traditional concrete pipes and metal pipes. According to industry analysis, the output of HDPE double-wall corrugated pipes in our country is nearly 500,000 tons in 2022, and it is expected to continue to grow in the future, becoming an important direction for the upgrading of the pipeline industry.

industry insiders pointed out that the high-ring stiffness characteristics of HDPE-M double-wall corrugated pipes not only improve the quality and safety of the project, but also provide strong support for urban construction and sustainable development by reducing the difficulty of construction and reducing maintenance costs. With the continuous innovation of technology and the improvement of standards, this product will further promote the pipeline industry to develop in the direction of high efficiency, durability and environmental protection, leading the industry to enter a new stage of development.